Equipment Design and Build

Client Requirements: The design process starts by understanding the specific needs of the manufacturing process. This includes the types of products to be produced, production volumes, desired production speeds, quality standards, and any other unique requirements (e.g., material handling, product handling, special features, etc.).

Industry Standards and Regulations: The equipment must meet industry standards (such as ISO, ANSI, or IEC) and adhere to safety regulations and guidelines specific to the industry, such as those set by OSHA, CE, or UL.

Conceptual Design and Feasibility Study

Initial Concept: A conceptual design is developed based on client requirements.

Feasibility Study: A feasibility study assesses the practicality of the design, including cost estimation, the availability of materials, and the ability of the design to meet performance and safety standards.

Detailed Design

Mechanical/Electrical Design / Automation and Control Systems design.

Prototyping and Testing

After completing the detailed design, a prototype is built to test the functionality, performance, and safety of the equipment. The prototype undergoes various tests to ensure it meets the required specifications. This includes functionality tests, load tests, safety checks, and performance evaluations. Issues identified during testing are addressed through design modifications or adjustments.

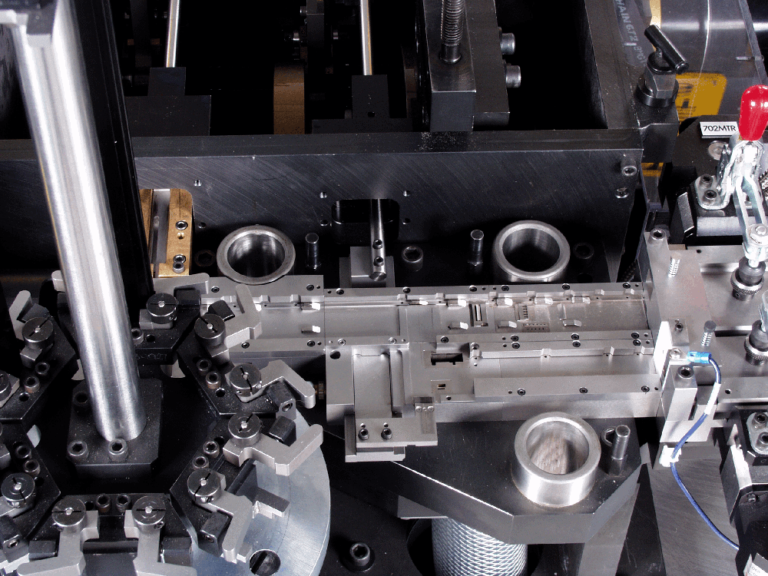

Fabrication and Manufacturing

Materials Selection / Component manufacturing, assembly, testing and Quality control.

The Challenges You Face

When it comes to complex equipment design or integration, many companies struggle with:- Finding specialized expertise that understands your unique requirements.

- Meeting stringent quality standards while controlling costs.

- Coordinating complex technical requirements across multiple disciplines.

- Scaling production capabilities without sacrificing quality.

The Real Cost of Suboptimal Design and Manufacturing

Without expert system design and integration, your projects face:- Significant delays in product development.

- Expensive rework and quality issues.

- Competitive disadvantage in fast-moving markets.

- Higher overall project costs and extended timelines.

The Apillis Equipment Design and Integration Advantage

Our specialized approach delivers exceptional results for your most demanding system design and integration needsExperience and Expertise

Our years of domain expertise and experience ensures that you receive an excellent designed or integrated product

Quality and Standards

Apillis applies the highest quality standards, whether it is a prototype system or a high volume production unit

Scalability

Apillis has US based design and manufacturing for fast turn NPI projects and Vietnam for high volume production

Related Services

EQUIPMENT DESIGN AND BUILD

Apillis's vertically integrated process allows us to shorten design to prototype to production cycle times of simple to complex equipment builds in our local facilities in California

AUTOMATION

Apillis specializes in automation of manufacturing assembly processes using standard equipment to fully customized automation equipment for complex applications

PRECISION MACHINING

Apillis is a precision machine shop for parts fabrication using in-house 4 and 5 axis CNC mill and lathe machines, sheet metal, welded and extruded equipment frames

The Resource-Optimized Development Guide

5 Strategies for Accelerating Technical Innovation with Limited Teams

- Learn how to prioritize technical development efficiently.

- Discover outsourcing strategies that actually work.

- Case studies from semiconductor and energy companies.